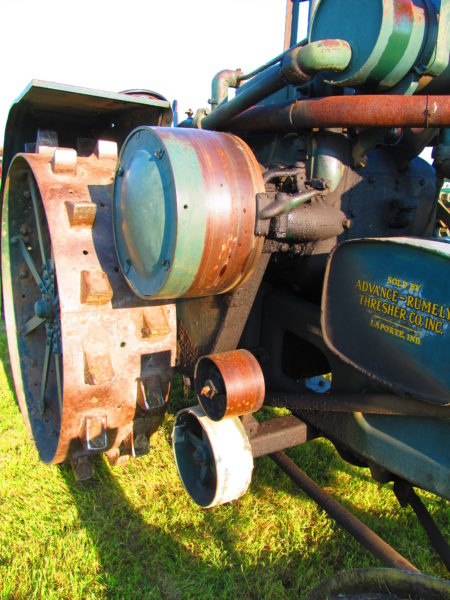

John Jordan of the Altamont area owned this Model F Rumely tractor. John Jordan homesteaded in the area and went on to become a successful farmer. The Jordan family still farms in the area.

John purchased the Model F when it was new along with a Rumely plow and a Rumely threshing machine. The Rumely warehouse in Winnipeg shipped all three pieces by train to Altamont where they were unloaded. John took delivery of the equipment at the station and used the Model F to tow the plow and threshing machine home. John had five sons, one of whom, Brooks Jordan, was nominated to be the operator of the Model F.

The Jordan family owned another Model F however family memories are not clear enough to determine if the two Model Fs were owned by the Jordan family at the same time. The other Model F was sold into the United States where it still exists and is also known as the “Jordan” engine.

In 1963, the Jordan Family donated the Model F along with its running mates, the Rumely Plow and the Rumely threshing machine, to the Manitoba Agricultural Museum. The Jordan “outfit” is one of three outfits in the collection and the most complete. The Williamson outfit consists of a 1904 25 Case steam engine and a Case separator both purchased together and used by the Williamson family in the Oak Lake area. The Bain outfit consists of a Marshall Model F Colonial tractor and an Avery power lift engine plow, again both purchased together and used by the Bain family in the Grosse Isle area. Only with the Jordan outfit did the engine, plow and threshing machine come as a three piece outfit to the Museum.

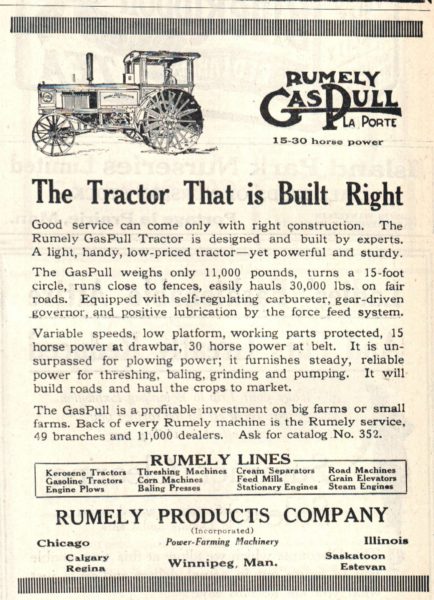

The Model F is a single cylinder tractor producing 15 horsepower on the drawbar and 30 horsepower on the belt. The design was in production from 1911 to 1918 with 3,856 being built. During the production run of the “F” the tractor was re-rated to 18-35. Along with the Secor-Higgins carburetor, the tractor was factory equipped with a Bosch magneto powering a make or break ignition system, an automatic throttle governor, mechanical oiler, a centrifugal cooling oil pump, a cooling oil radiator cooled by exhaust induced draft and a compressed air starter.

Rumely was a builder of farm machinery, but best known for the Rumely Oil-Pull line of tractors. Over the course of the Rumely Company’s life, it accumulated other farm machinery companies including the Advance Thresher and Gaar-Scot companies. After these acquisitions, the company became known as the Advance-Rumely Company.

The Rumely Company originally got its start when Meinrad Rumely left Germany and joined his brother in LaPorte, Indiana to operate a foundry. By 1859, the brothers were making corn shellers and horse powered threshing machines. The brothers went on to produce steam engines and a variety of other farm machinery including clover hullers, plows, cutting boxes, corn shellers, corn shredders, silo fillers, water wagons, cream separators and motor trucks. By 1925, the company was building pull type combines.

While Rumely was not in the first wave of gas tractor manufacturers, by 1909 it had entered the market with its Oil-Pull line of tractors which were immediately popular as they proved to be simple, rugged, reliable tractors. This line of tractors could burn kerosene or distillate fuels.

Kerosene became common as a tractor fuel in the years before World War one. At that time, rapidly increasing numbers of automobiles were driving up the price of gas in comparison to kerosene. As well, kerosene is heavier than gas and contains somewhat more energy per gallon. The combination of the two factors, made kerosene very attractive as a fuel for farmers.

Kerosene was cheaper than gas as a result of the technical limitations of early refineries. Without efficient methods of breaking down hydrocarbon chains large amounts of kerosene and distillate were produced in the refining of crude oil into gas.

Gas vaporizes much better than kerosene plus kerosene poses pre-ignition problems. Auto makers preferred gas powered engines for these reasons. Tractor manufacturers however realized that they could successfully use kerosene and distillate by adding heat into the carburetion systems which then vaporized the kerosene and distillate to the point where efficient ignition could take place. Pre-ignition could be controlled by mixing water into the fuel charge flowing into the cylinder. The only drawback was how to get a cold engine to start on kerosene or distillate but someone realized that this problem was solved by starting the engine on gas and when the engine was warmed up switch it over to kerosene or distillate. While this process was more complicated than a gasoline engine, with a tractor hopefully the operator was more familiar with engines than the average car owner of the time and so could more closely monitor and regulate the system.

The lower cost of kerosene and distillate proved very attractive to tractor users. Most tractors built before 1910 burnt gasoline however after 1910 the situation reversed with most tractors being built, able to burn kerosene or distillate as the main fuel.

The Rumely Oil-Pull engine design used a higher compression engine than what had previously been found in tractors which aided in burning kerosene and distillate. The Oil-Pull line also used the Seccor-Higgins carburetor which efficiently mixed water with the fuel under all loads. Other designs required manual adjustments but the Seccor-Higgins automatically adjusted itself. The Seccor-Higgins could be set to handle other fuels than kerosene.

Oil-Pull tractors were cooled by oil, not water, as oil allowed an higher engine operating temperature making burning kerosene or distillate more efficient plus oil did not freeze. As a result of the cooling fluid being oil, a leaking head gasket could pose serious problems. Cooling oil could be drawn into the cylinder and then burnt there. The governor would not be operating as this oil was coming through the head gasket, not through the carburetor and so the engine could “run away” or begin increasing rpm. Unless the operator recognized the problem quickly and managed to block the engine air intake off or somehow place an excessive load on the engine causing it to stall, the engine rpm would increase to the point where the engine would exceed its design speeds and fly apart.

Rumely built a number of models of the Oil-Pull starting with the “B” and progressing on to the “E”, “F”, “G”, “H” and “K”.

The Model F is a single cylinder tractor producing 15 horsepower on the drawbar and 30 horsepower on the belt. The design was in production from 1911 to 1918 with 3,856 being built. During the production run of the “F” the tractor was re-rated to 18-35. Along with the Secor-Higgins carburetor, the tractor was factory equipped with a Bosch magneto powering a make or break ignition system, an automatic throttle governor, mechanical oiler, a centrifugal cooling oil pump, a cooling oil radiator cooled by exhaust induced draft and a compressed air starter.

The great depression resulted in the Advance–Rumely Company encountering financial difficulties. Allis-Chalmers purchased the company, mainly for the dealer network that Rumely had built up. Allis kept the Rumely 6A tractor, an up to date design, in production as well as the Rumely combines but all other Rumely machinery was discontinued.