The Murray Brothers of Lyleton, Manitoba donated a Rumely Model M Oil Pull tractor to the Manitoba Agricultural Museum.

The Advance Rumely Company brought out the Light Weight Oil Pull Model M 20-35 in 1924. The Light Weight line of Oil Pulls was termed this as the frame of these tractor models was built of pressed steel rather than the heavy channel iron riveted together. Along with a redesigned frame, the engines used in the Light Weight series of tractors were also redesigned as well as the transmissions and drive trains. The open gears used to drive the rear wheels on the Heavy Weights were done away with and the gear train was now enclosed in oil. This was a big advantage as dust wore the open gears badly.

The Model M featured a 2 cylinder, horizontal, valve in head engine with removable cylinder sleeves. The bore was 6 13/16 inches with a stroke of 8 1/4 inches. A fly-ball governor of the Advance Rumely Company’s design was fitted. An Donaldson air cleaner of the oiled fibre type was also fitted. A Manzel lubricator was also fitted to provide forced oil feed to engine bearings. As well, splash lubrication was provided by the connecting rods moving through the oil in the bottom of the crankcase. As with all Oil Pulls, a Seccor-Higgins carburetor was fitted. The transmission provided 3 speeds ahead and one in reverse. The weight of the Model M was 8,750 pounds.

Advance Rumely Model Ms were built from 1924 to 1927. The Murray Brothers Model M has a serial number of 3524 making it built in 1927.

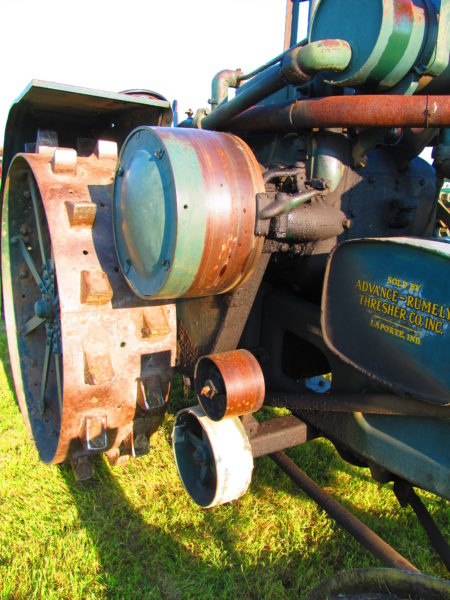

The Murray Model M features an optional Power Take Off (PTO). The PTO by 1924 was becoming a desirable feature in a tractor as the tractor could power a binder rather the binder being powered by the binder’s bull wheel or an auxiliary engine mounted on the binder. As well, PTOs made other labour saving farm machinery possible. The Rumely PTO was an add on attachment. A belt off the belt pulley drove a shaft that crossed underneath the tractor. At the end of this shaft was a small 90 degree gear box that drove a shaft that ran to the back of the tractor on the left side. It would appear that this gear box could be engaged or disengaged as it is fitted with a lever. Of course the belt pulley has to be engaged to operate this PTO making this “dead” PTO. That is when the clutch was operated to stop the tractor moving, the belt pulley and the PTO also came to a halt. In field operations this was a significant disadvantage.

At the time PTOs were relatively new and no standards, American Society of Mechanical Engineers (ASME) or otherwise were in force in 1924. So Rumely was free to do as it pleased which explains why Rumely located the PTO shaft tight to the left hand rear fender. To say the least this made hooking any other make of PTO operated machine than an Advance Rumely designed machine to this tractor, somewhat of an adventure. At a later date, ASME standards as to the height and position of the PTO on the tractor in relation to the drawbar came into being, making the mating of PTO driven machinery and tractors far more interchangeable.