Manufactured by the Massey Harris Company

With the death of J.I. Case in 1891 and the resulting financial troubles, the Case group of companies was split into two entities, the J.I. Case Threshing Machine Company and the J.I. Case Plow Works. Henry Wallis a son-in-law of J.I. Case took over J.I. Case Plow Works in 1892.

Having two companies J.I. Case Threshing Machine Company and J.I. Case Plow Works was a source of confusion which led to legal action between the two companies. J.I. Case Threshing Machine Company was the company which built the Case steam engines and gas tractors.

In 1912 Henry Wallis entered the tractor business and established the Wallis Tractor Company. Right from the start the Wallis Tractor Company built tractors that were well engineered. The 1914 Cub tractor model introduced an important innovation the use of boiler plate formed into a U shape which then formed the engine crankcase and the case for the transmission. A bulkhead divided the crankcase and transmission case. This one piece case provided a stiff foundation for the tractor. Enclosed final drives soon followed. Wallis used roller bearings where possible and was known for the use of high quality materials in construction.

By 1927 Wallis tractors had evolved substantially. The Cub has evolved through the Cub Junior, Model K, Model OK, Certified 15-27 into the 20-30. The 20-30 featured a four cylinder engine with 4.375 inch bore and 5.75 inch stroke, Kingston Model L carburetor, American Bosch ZU4 magneto, Kingston governor, internal engine lubricating oil pump and oil bath air cleaner. The tractor came with a Power take off and a three speed transmission. In 1928, the J.I. Case Plow Works was purchased by Massey Harris (MH). Wallis was part of this company and MH continued selling Wallis tractors under the Wallis name until 1932. At that time the Model 20-30 was upgraded into the Model 25 which was sold as Massey Harris with the Wallis name disappearing from production.

While Massey Harris (MH) did not produce steam engines, the Massey family had a significant financial interest in the Sawyer Massey Company which did build steamers. However in 1910 there was a disagreement over producing gas tractors which resulted in the Massy family selling their interest in Sawyer Massey. However the Massey family remained interested in gas tractors. The Sawyer Massey experience did point out to the Massey family that engine development was expensive so outside engine suppliers or purchasing a tractor from another manufacturer were options to consider for MH.

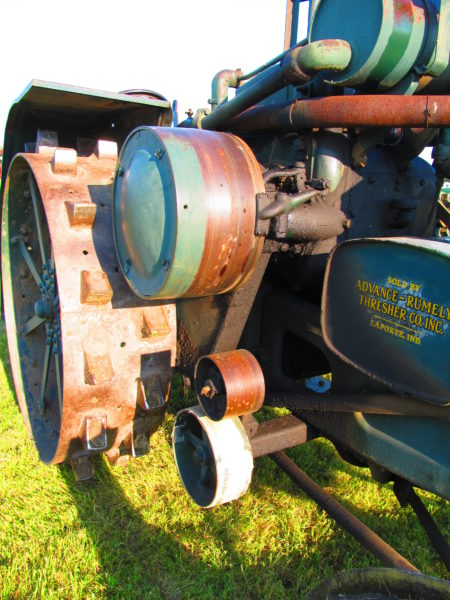

In 1917, MH attempted to secure the popular US made Bull tractor, for sale through its dealers. However the deal fell apart. MH then secured the manufacturing rights to the Parrett tractor. The tractor entered production in Toronto in 1918 and stayed in production until late 1922 going through three versions which incorporated various improvements. In 1922, MH realized it could not compete with the Fordson tractor which cost 1/3 the price of the MH Parrett so MH ceased production of the tractor. However MH realized that the lack of tractor line placed MH at a disadvantage compared to companies like IHC. A tractor line was needed and MH then attempted to strike an agreement with the J.I. Case Plow Works to sell this company’s line of Wallis tractors in Canada through MH dealers. In 1928, after complicated negotiations, MH purchased the J.I. Case Plow Works, immediately selling the name to the J.I. Case Threshing Machine Company for ½ the price MH had purchased the entire company for. The purchase of the Plow Works gave MH production plants in the US.MH sold Wallis tractors until 1932 when the tractors were re-badged as Massey Harris.