The Model F in the museum’s collection was donated in the early 1960s by the family of Benjamin Miller Bain (1871-1960) of the Grosse Isle area. The Bains purchased the tractor new and used it on their farm near Grosse Isle. At the time the tractor was donated the eight bottom Avery power lift plow that was purchased new with the tractor was also donated to the museum where it remains.

The tractor, seen here in 2010, had just returned from a three-year restoration undertaken by museum volunteers Keith Munro, Norm Lepoder, Gilbert Vust, Alvin Vust, and Jeff Nicoljsen.

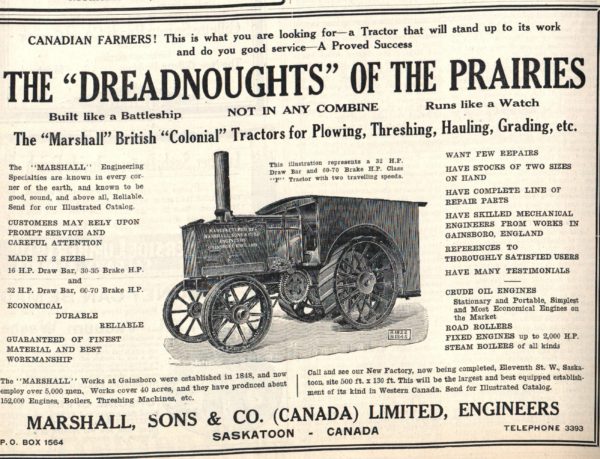

Marshall and Sons was a Gainsborough, England farm machinery manufacturer that built steam engines, threshing machines, and other machinery. The company decided to enter the kerosene tractor business and built what are termed the “Colonial” tractors in the decade before the First World War. These Colonial tractors were meant for the “colonies”: Canada, Australia, India, and South Africa but were also sold in South America. The motto Marshall and Sons used for the Colonial tractor was “Built like a battleship and runs like a watch.” This particular tractor is a four-cylinder Model F dating from 1914 and has a rating of 32-70 (32 horsepower on the drawbar and 70 horsepower on the belt).

A Colonial tractor was tested at the 1909 Light Agricultural Motor Competition held at the Winnipeg Exhibition. The statistics from this competition indicate this tractor had a four-cylinder engine with a rating of 25-60, a weight of 22,000 pounds, and a price of $3,400. This tractor may have been a Model D. Marshall also built a two-cylinder Colonial tractor and one appeared in the 1908 Light Agricultural Motor Competition.

The number of Colonial tractors built is unknown but thought to be small. Of the larger four-cylinder Colonials, there are five complete tractors left in the world with parts of a sixth perhaps in Saskatchewan. Three of the existing five are in Canada: a Model D at the Reynolds Museum in Alberta, a Model D at the Western Development Museum in Saskatoon, and a Model F at the Manitoba Agricultural Museum. There is a Model F in Australia and a Model F in England which was returned there from Australia by a tractor collector. There may be a two-cylinder Colonial in the possession of a British collector who has emigrated to Canada.

With the advent of the First World War, Colonial tractor production came to an end. Marshall resumed tractor production after the war and, by 1928, had produced a tractor similar to the Lanz Bulldog which evolved by 1944 into the Field Marshall tractor. Marshall merged with Fowler, another English farm machinery manufacturer, in 1947, and the new firm concentrated on building bulldozers and later bought the Leylands tractor line. New tractor models failed to gain market acceptance and by 1995 Marshall-Fowler had closed.

Restoration

Over the years at the museum, the years of work the Model F had put in caught up with it. The most pressing problem was the repeated cracking of the engine water jackets. As it was such a rare and unique tractor, Portage residents Keith Munro, Norm Lepoder, Gilbert Vust, and Alvin Vust decided to take the tractor under their care and restore it. They received permission to remove it from the Museum and take it to Munro’s farm where they could more easily work on it. A three-year restoration effort began. During the course of this work, the cracked cylinder jackets were properly welded with a replacement cylinder obtained to replace the cylinder that was most difficult to repair. It made no sense to undertake a difficult repair when a replacement in good condition was available. The drive gears were built up, worn shafts in the transmission were built up, a rotted side wall of the tank-type radiator was replaced, and a cracked transmission case was repaired. Norm Lepoder performed much of the early welding on the tractor; however, work circumstances changed and he was not available for the last half of the project. Jeff Nicolasen of Sperling Industries agreed to complete the welding. In general, the welding on the tractor was complex and demanding. The cylinder jackets were particularly difficult as they are quite thin.

During the work on the transmission, it was discovered that the castings that make up the case had been incorrectly reassembled at some time. When reassembled in the proper positions following the matching numbers on the various pieces making up the case, the case and shafts fit much better and the team was able to discard numerous shims.

A major job was the tank-style radiator. When the top of the tank was removed, the team found that the interior of the large square tank that makes up the hopper was partially filled with debris from various sources. This debris also clogged the jackets so that when the plugs in the jackets were removed to drain them, water would not drain properly. The interior of the tank is not empty but contains two separate stacks of vertical plates with diamond shaped holes punched in the plates with an upward facing lip on these holes. Each plate is separated from the other plates by a wooden former running around the perimeter of the plate. A system of baffles separates the two stacks of plates. The tank was cleaned out and the plates with new wooden formers were reinstalled. As well, there was supposed to be a system of pipes running across the top of the tank with holes in the bottom of the pipes. These pipes carried hot water from the engine and evenly dribbled the water down over the plates. The water then ran down through the holes in the plates. As these pipes were missing, new pipes were fabricated and installed.

Tank- and hopper-type radiators were common in the earlier years of tractors; however, they used water at a great rate. The Marshall was no exception as the exhaust was turned into the base of a stack on the top of the tank. As the exhaust escaped up the stack, a draft was created which pulled cool air into the tank through hooded slots on top of the tank. The baffles in the tank directed the air down through the holes in the plates before allowing the air to go up and out the stack. Obviously in this process much water would be lost along with the heat from the engine.

The restoration team sent out the Bosch ignition system for repair and fabricated some missing parts. There was a small crank missing at the back of the engine. The purpose of this crank was not to crank-start the engine directly but to properly position the pistons in the cylinders for starting. A cylinder would be primed with gas and a button pressed that would cause the spark plug to spark hopefully detonating the gas, turning over the engine and starting it. Wooden forms were carved and new parts were cast from these forms so this crank could be duplicated and installed. Starting the early, large gas/kerosene tractors was a significant problem as a result of poor quality fuels, primitive ignition/carburetor systems, and farmers’ lack of experience with mechanical systems. The usual method of starting involved turning over the exposed flywheels but some tractors had a one-cylinder gas engine as a pup starter while the Bosch system appeared on other tractors besides the Marshall. A problem with the Marshall was that if this system failed, the only alternative was either pull start it or belt start it, both of which required another tractor. The flywheel on this engine cannot be accessed to turn over by hand. The team has started the tractor with the Bosch system but feels it would have worked better when the tractor was new with the engine and carburetor system in top condition. Further running of the engine to seat the rings and valves may improve compression and also improve starting by the Bosch system.

The final step in the restoration was the painting of the tractor. In the course of researching the color scheme, the team discovered that the owner could order whatever scheme the owner wanted. After examining the tractor, the team believes the original paint job featured orange wheels with everything else a dark green. This paint scheme was applied. Proper lettering decals were sourced.

The museum decided that the proper place for this tractor was on display in the Heritage Building. Between the rare nature of this tractor and the complex radiator, static display with the engine being turned over on a regular basis was the best option. As well as the Marshall, the Williamson Case steam engine and threshing machine are slated to go on display in the Heritage Building. Other pieces are being selected to add to this display. Proper signage will be developed and put up.

During the course of researching the tractor, the team was told there were 30 Model Fs in Saskatoon at the beginning of the First World War which were purchased by the Russian army to tow artillery pieces and shipped off to Russia. So if you want a Model F perhaps a search of the wilderness that still makes up large areas of the former eastern front will reveal a Model F. But, in the mean time, you can see one at the Manitoba Agricultural Museum.

The Marshall restoration team of Gilbert Vust, Keith Munro, Alvin Vust, Norm Lepoder, and Jeff Nicolajsen have done a tremendous job of restoring a rare piece of Manitoba’s agricultural history. Coming out to see this tractor and the work necessary to bring it back to a factory condition would be one way to show appreciation to this team for all their hard work on behalf of the museum and the citizens of Manitoba.