With the new Model 20 performing well with big acreage growers, including export demand from countries such as the USA and Argentina, Tom Carroll and the combine design team at MH quickly set to work designing a smaller SP combine two-thirds the size of the No.20. The aim was to develop a new smaller, lighter and more affordable self-propelled combine that would sell in large numbers to smaller farms.

The resulting machine had a 12-foot cut and was built much lower with the engine underneath. The table used draper canvases. These did a nice job of feeding the grain heads into the feeder house. It was priced within range of the”average” farmer.

Sales of the Model 20 totaled 925 machines over two years, but when the new MH-21 combine arrived in 1941, it created a huge demand with annual production peaking at 10,000 plus in 1949. However in the war years of 1939 to 1945 steel supplies limited production along with shortages of components such as the Chrysler six cylinder engines.

During the Second World War Massey-Harris and the Model 21, pioneered the “Harvesting Brigade”. The company gained permission to build a fleet of 500 Model 21s and sell them to custom operators who were to work north from the southern states of the US Great Plains area and in doing so follow the ripening harvest north. Materials such as steel, engines and other components were rationed during the war in order to ensure allied military forces had sufficient supplies. Massey Harris had to convince the authorities that 500 Model 21s were sufficiently valuable to the Allies cause that materials could be allocated to build them along with the factory space as Massey Harris plants had been converted to build a variety of military equipment. Massey Harris made their case for the materials and plant space by pointing out the machines would save labor, release tractors for other uses and tractors were in short supply at the time plus the machines would reduce harvest losses due to tramping grain when opening up fields with pull type combines or to broken sheaves if the field were being harvested by binder and threshing machine.

The plan worked as the machines harvested more than a million acres in one year and freed up an estimated 1,000 tractors for other work while doing so. Massey Harris worked hard to ensure the program was a success by positioning spare parts along the route north through the Great Plains.

Even more importantly for Massey Harris, the Harvest Brigade had given a large number of farmers a very positive impression of Massey Harris self propelled combines. When the war ended, and they were able to switch back to normal production, demand for Massey Harris combines was immediate.

After the war Massey Harris introduced the Massey Harris Model 21A which used an auger on the table instead of draper canvases to feed grain into the feeder house. However the Model 21A auger did not feature disappearing fingers.

With the MH-20 and MH-21 combines Massey-Harris achieved an important breakthrough in grain harvesting, which other combine manufacturers were forced to follow.

Tom Carroll’s role in the development of the Massey Harris combines was not forgotten and he was awarded a Gold Medal in 1958 by the American Society of Agricultural Engineers to recognize his contribution to combine harvester development. Along with the first successful self propelled combine, Tom Carroll helped introduce to the farm machinery business mechanical improvements such as welding, roller chain, oil bath gear sets, ball bearings and detachable tables which made combines easier to transport.

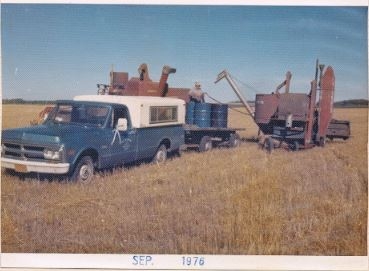

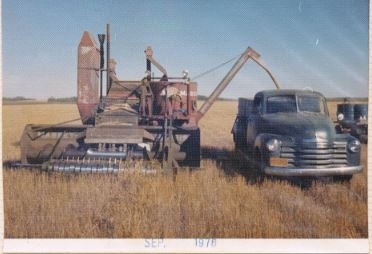

Beamish Family Massey Harris Model 21 Combine

The Museum has two Model 21s in the collection and both operate.

The Beamish Family donated this Model 21 to the Museum in 1979. The machine was purchased new in 1947 by Douglas and Richard (Dick) Beamish. When new the machine was fitted with a canvas draper pickup table. The machine was joined in handling the Beamish harvest by a Massey Super 27 in the late 1950s. In 1967, the pickup table was changed to the auger type making the machine equivalent to a Model 21A. The Model 21 and the Super 27 soldered onwards but with the finish of the 1979 harvest they were retired. The Model 21 was donated to the Museum at that time.

The other Model 21 in the collection is still fitted with the canvas draper pickup table and is an earlier machine than the Beamish Model 21 as it is fitted with galvanized sheet metal. Originally the Model 21s were built with galvanized sheet metal and later production used painted sheet metal. Originally the Beamish machine sported a red paint job but time has turned the sheet metal to a patina of brown and surface rust.